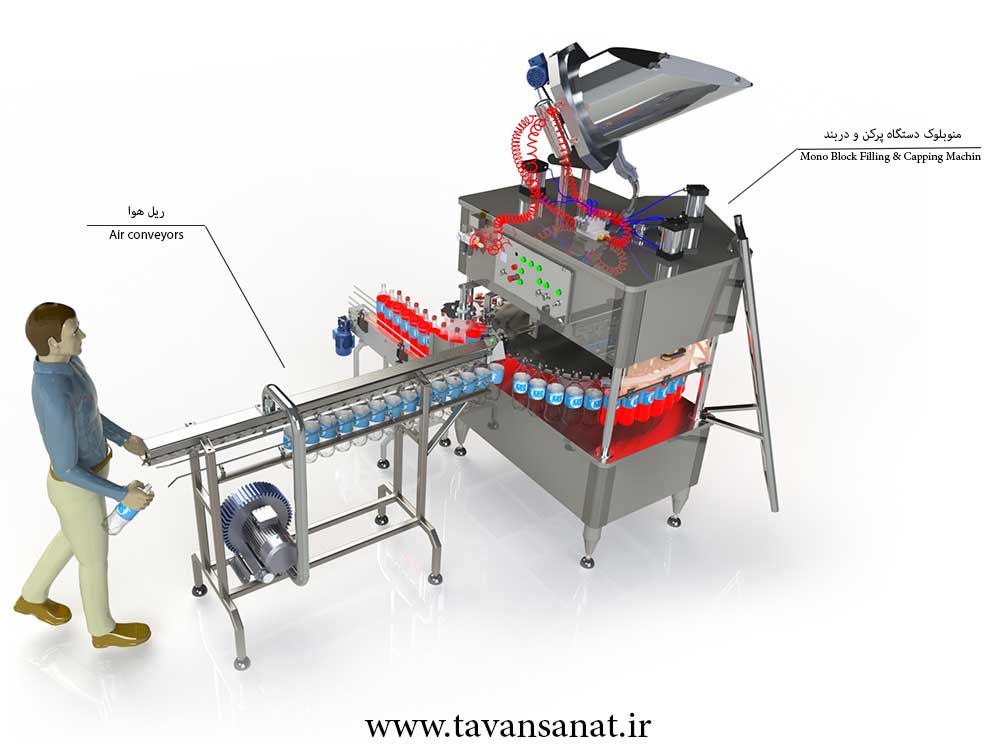

Three Block

TRI–Block machine of the pet bottles is used for bottling drinking without gas equipped with three-stage cleaning bottles with 12 woodseller filling Nozzles and a tank for leaving the bottle lid with a capacity of 3,000 lids and six head capping, a maximum speed of FTB12 TRI–Block is 3800 bottles per hour which is easily customizable depending on the bottle size and production capacity through the power panel. Although the rate of 3800 bottles doesn’t need to unscrambler machines, but TRI -Block device has been equipped with an air conveyor, and it can be connected to machines such as blow molding and unscrambler machines. The design of this device in addition to maintaining high quality and performance has had a significant impact on the reducing costs and it has very reasonable price depending on the production rate of the plant, which it is considered as one of the top benefits of the TRI –Block device.

Washing bottles in the device is done by three separate nozzles. Each nozzle is equipped with a sensor which if not putting bottles on conveyor air, sprinkler nozzle valve won’t be opened to save water. Using the sink placed under the sprinkler nozzles, water in bottles is washed and removed from sewage pipes, and can be used after the filter again.

In case of not putting bottles on the TRI -Block air conveyor, the device will turn off automatically after 10 minutes and this time can be adjusted through the HMI display. The Nozzles of TRI –Block device to fill bottles are equipped with air discharge tube and return the product to the tank, and the open impeller pump is used to speed up the filler in the milk and dairy industries.

توضیحات تکمیلی

| وزن | 1450 کیلوگرم |

|---|---|

| ابعاد | 310 × 180 × 290 سانتیمتر |

| مدل | FTB12 |

| ظرفیت تولید | 3800 Bottle 300 cc |

| مصرف برق | 5.7kw |

| مصرف باد | 7 Bar |

ارسال و نصب در تمای نقاط کشور

989152000058+ ساعات پاسخ گویی 9 الی 4 عصر

شرایط پرداخت

سفارش دستگاه

گارانتی معتبر

با کالاصنعت

راهنمای خرید

ماشین سازی توان صنعت در بعد صادرات، با توجه به خط مشی شرکت، رقابت در بازار های خارجی ( کشورهای همسایه ) را جزء برنامه های اساسی خود قرار داده، به نحوی که در حال حاضر صادرات به کشور های زیر انجام می پذیرد: پاکستان، ترکیه، عربستان، ترکمنستان ، قرقیزستان ، افغانستان و برخی از کشورهای آفریقایی.مدیریت ماشین سازی توان صنعت ، با التزام به موارد فوق کلیه کادر شرکت را موظف به پایبندی به موارد و اهداف عالیه فوق نموده است. اهميت به نظرات مشتري جزء مهمترين برنامه هاي اين شركت است . به نحوي كه توان صنعت هميشه منتظر پيشنهادات و انتقادات مشتريانش مي باشد .

تمامی مطالب ، عکس ها و … مطعلق به سایت توان صنعت می باشد .